Project title: Biopolymer structures obtained by plasma treatment for wounds healing – BIOPLASM

Project coordinator: ICECHIM, dr. eng. Denis Mihaela Panaitescu

Project code: PN-III-P2-2.1-PED-2021-2559

Project number: 632 PED/2022

Implementation period: 21.06.2022 – 20.06.2024

Funding: The Executive Unit for the Financing of Higher Education, Research, Development and Innovation (UEFISCDI)

Project summary:

Chronic wounds, severe burns or infected wounds are among the most painful diseases that require long-term expensive treatment. Currently, the clinical management of chronic wounds is difficult due to the increasing risk of infection with antibiotic-resistant bacteria and the shortcomings of current therapies. A novel technology for the manufacture of bilayer wound dressings, based on nanocellulose and cold plasma processing, will be developed in BIOPLASM project. The scope of the project is to obtain effective dressings for the treatment of infected wounds by developing antibacterial nanocellulose nanocarriers deposited on an aliphatic polyester substrate. The use of cold plasma for nanocellulose and biopolymers processing in view of medical application is an effervescent field, with important benefits related to eco-friendliness, lack of secondary or waste products, sterilization and large functionalization capabilities. Cold plasma treatment of liquid suspensions of nanocellulose is a concept developed by ICECHIM and INFLPR in a previous project. This will serve as a starting point together with the functionalization and processing of nanocellulose and aliphatic polyesters for building a new technological approach to fabricate bilayer wound dressings. The new technology will be validated by in vitro and in vivo studies. The project will be implemented by a skilled group of researchers from ICECHIM, INFLPR and Cantacuzino Institute.

The general objective of BIOPLASM project is the development and lab-validation of a new technology for the manufacture of bilayer wound

dressings based on nanocellulose and cold plasma processing.

The project has the following specific objectives:

– Designing new nanocarriers based on nanocellulose (NC);

– Synthesis of NC carrying different antibacterial agents and testing new technological routes for the deposition of nanocarriers on plasma activated

biopolymer substrate;

– Characterization of structure and morphology, thermal and mechanical properties of the obtained layered structures;

– Characterization of in vitro cytotoxicity and antimicrobial activity of layered wound dressings; selection of the optimum technological solution;

– Demonstrating the performance and validation of the new technology for manufacturing bilayer wound dressings.

The outcome of the project is an innovative technology to obtain bilayer dressings for the therapy of infected wounds.

The most important results: antibacterial nanocarriers based on modified nanocellulose and bilayer dressings with antimicrobial activity. The results will be disseminated by communications at national and international conferences, one workshop and five papers.

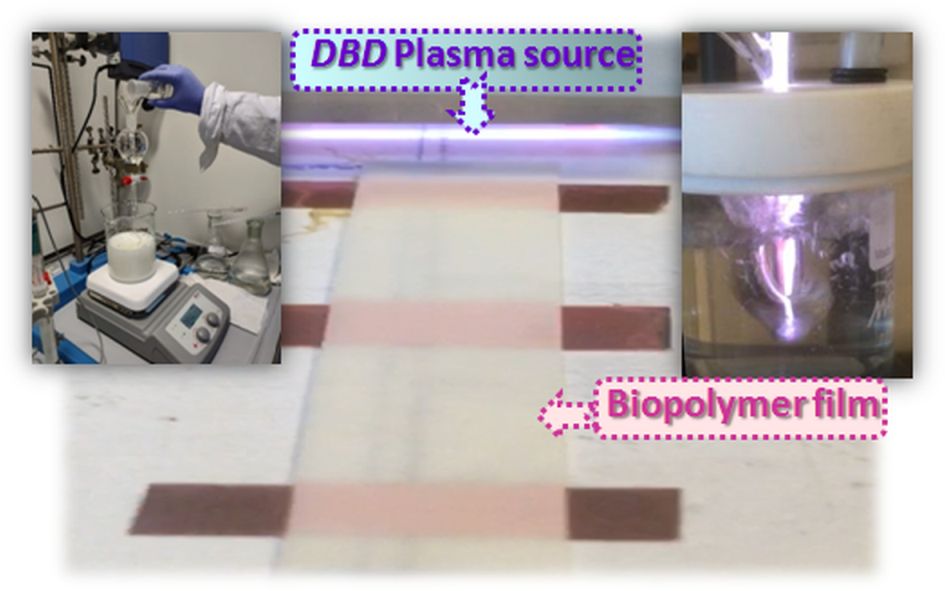

Phase I:

In this phase, nanocarriers based on nanocellulose (NC) were synthesized using TEMPO oxidation, functionalization with silanes and plasma immersed in the nanocellulose suspension for NC activation. The efficiency of the treatments applied and the changes induced on the NC surface were highlighted by electron microscopy, infrared spectroscopy, XPS and thermogravimetric analysis. NC functionalized or not was impregnated with extracts of natural antibacterial agents in ethanol in proportions of 5 and 10% resulting in ANC(I) nanocarriers that were characterized in terms of structure, morphology and thermal properties. The results indicated that the natural antibacterial agents adhered to the cellulosic substrate and did not reduce the thermal stability of the nanocellulose. Cytotoxicity tests showed an important effect of the antibacterial agents in ANC(I) on cell viability. The biopolymer substrate was also fabricated from several polymer blends whose main component was poly(3-hydroxybutyrate-co-hydroxyvalerate) that was modified with various elastomers. Films of these polymer blends were treated with cold plasma under different conditions (different number of scans, single gas or mixture of gases) for surface activation. For this purpose, a planar DBD plasma source was created, operating at atmospheric pressure and mounted on a translation table. The morpho-structural characterization by X-ray photoelectronic spectrometry and SEM as well as the thermal and mechanical-dynamic analysis of the substrate before and after the cold plasma treatment highlighted the influence of this treatment on the surface structure, thermal stability and mechanical resistance of the biopolymer support.

Phase II

During this stage, antibacterial carriers based on nanocellulose were developed and experiments were carried out to obtain bilayered dressings containing these antibacterial carriers. The morpho-structural characterization of the nanocarriers by FTIR and SEM as well as the thermal and mechanical characterization highlighted the modification of the nanocellulose due to the incorporated antibacterial agents. For Pickering emulsion type nanocarriers, their stability and variation of stability over time was also determined. The cytotoxicity analysis report indicated a cell viability of over 90% for all tested samples, which indicates that the ANC carriers are not toxic and present a high degree of biocompatibility. Also, ANC carriers have an antibacterial effect tested in the case of Staphylococcus aureus. Based on these results, the most advantageous solution was selected, which was tested by covering biopolymer films to obtain bilayered dressings. The experiments of plasma activation of the substrate and spraying of the selected nanocarriers allowed establishing the technological conditions for making the dressings. They were characterized by morpho-structural, thermal and mechanical analyses, the results highlighting better properties after plasma treatment and coating with nanocarriers.

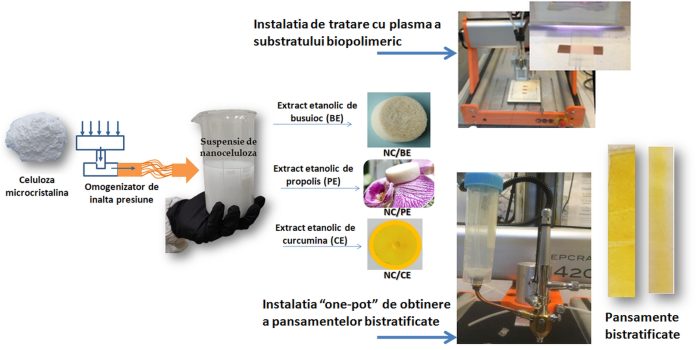

Phase III

In this phase, a new “one-pot” procedure for obtaining antibacterial layered dressings that involves the activation of the support by using a cold plasma jet and the application of antibacterial nanocarriers ANC in a single phase by spraying was developed. For this purpose, a new experimental setup was created in which the plasma source and the spray source are mounted on the same translation table. In order to improve the quality of the layered dressings obtained by the “one-pot” process, the suspensions of antibacterial nanocarriers were modified for a better adhesion to the biopolymeric substrate by the addition of biocompatible polymers. The laboratory technology for making bilayered antibacterial dressings was developed and demonstrated by obtaining and characterizing a representative number of dressings applying the two technological variants developed within the project. Both technological variants present advantages related to speed, simplicity, and productivity in addition to the fact that they are environmentally friendly. The first variant requires a plasma generation facility, the second can be applied even without it. The analysis report of the in vivo antimicrobial activity in the case of the application of the antimicrobial dressings on wounds infected with Methicillin-resistant Staphylococcus aureus (MRSA) highlighted the healing after 4 days. The laboratory technology for obtaining the antibacterial layered dressings was validated based on the characteristics of the two-layered dressings made, which demonstrated the antibacterial effect and the presence of antimicrobial agents on their surface, as well as the maintenance of the mechanical and thermal stability properties at least at the level of those characteristic of the substrate. The obtained results were disseminated by submitting two patent applications, by communicating the results in the form of oral and poster presentations at 5 national and international conferences, by publishing an article and by updating the project web page.

Published papers:

- D. M. Panaitescu, V. Melinte, A. N. Frone, C. A. Nicolae, A. R. Gabor, L. Capra, Influence of biobased polyurethane structure on thermal and mechanical properties of poly(3- hydroxybutyrate-co-3-hydroxyvalerate) – polyurethane blends, Journal of polymers and the environment 2022, 31, 1584–1597 (2023).

- G. M. Oprică, D. M. Panaitescu; C. D. Usurelu, G. M. Vlăsceanu, P. O. Stanescu, B. E. Lixandru, V. Vasile, A. R. Gabor, C.-A Nicolae, M. Ghiurea, A. N. Frone, Nanocellulose Sponges Containing Antibacterial Basil Extract. Int. J. Mol. Sci. 2023, 24, 11871

- L. G. Coman, M. Marcu, T. Acsente, S. Vizireanu, V. Satulu, G. Dinescu, E. Matei, T. Spataru, N. Spataru, L. Preda, Hybrid nanostructures based on vertically graphenes decorated with tungsten oxide nanoparticles for enhanced capacitive performance, Diamond and Related Materials, 139, 2023, 110316

- C. D. Uşurelu, D. M. Panaitescu, Nanocellulose/Nanodiamond Hybrids: A Review. Macromol 2023, 3, 400-420.

- G. M. Oprică, D. M. Panaitescu, B. E. Lixandru, C. D. Uşurelu, A. R. Gabor, C.-A. Nicolae, R. C. Fierascu, A. N. Frone, Plant-derived nanocellulose with antibacterial activity for wound healing dressing, Pharmaceutics, 2023 15, 2672

- S. Vizireanu, I. Constantinoiu, V. Satulu, S. D. Stoica, C. Viespe, High-Sensitivity H2 and CH4 SAW Sensors with Carbon Nanowalls and Improvement in Their Performance after Plasma Treatment, Chemosensors 2023, 11(11), 566

- D. M. Panaitescu, C. Stancu, S. I. Vizireanu, V. Sătulu, M. Ghiurea, G. M. Oprică, C. D. Uşurelu, C. A. Nicolae, M. F. Raduly, A. N. Frone, Influence of cold plasma treatment on cellulose modification with different oxidizing agents (in preparation)

Patent applications:

- D. M. Panaitescu, A. N. Frone, G. M. Oprică, C. D. Uşurelu, A. C. Nicolae, A.R. Gabor, C. Firincă, S. Vizireanu, C. Stancu Procedeu de obṭinere a unor dispozitive medicale stratificate cu efect antibacterian din biopolimeri şi nanoceluloză ca nanopurtător al principiilor naturale active, brevet ICECHIM-INFLPR, A2024-00315/12.06.2024

- S. Vizireanu, C. Stancu, T. Acsente, C. Constantin, M. Valentina, S. Veronica, G. Dinescu, D. M. Panaitescu, A. N. Frone, A. M. Holban, F. Marinescu Sursa de plasma rece DBD liniara cu electrozi plani prevazuta cu injectie de gaze reactive direct in descarcare pentru procesare de suprafete extinse, brevet INFLPR-ICECHIM-UB, A2024-00330/14.06.2024

Communications:

- S. Vizireanu, V. Satulu, C. Stancu, A. Bonciu, G. Dinescu, D. Panaitescu, A. Frone, V. Raditoiu, C. Nicolae, C. Usurelu, Cold plasma activation of biopolymers for wound healing dressings, 22nd Romanian International Conference on Chemistry and Chemical Engineering, RICCCE 22, September 7-9, 2022, Sinaia, Romania (poster).

- C.-D. Uşurelu, A. N. Frone, C. A. Nicolae, A. R. Gabor, S. Vizireanu, V. Satulu, C. Stancu, S. M. Teodorescu, D. M. Panaitescu, A parallel between plasma irradiation of nanocellulose water suspensions and silane grafting as surface treatments of nanocellulose, The 7th International Colloquium on “Physics of Materials”, PM-7, November 10-11, 2022, Bucharest, Romania (poster).

- G. M. Oprică, C. D. Ușurelu, A. N. Frone, V. Rădițoiu, A. R. Gabor, C-A. Nicolae, D. M. Panaitescu, Influence of plant extract on the properties of nanocellulose, A cincea ediție a workshop-ului exploratoriu NeXT-Chem: Tehnologii inovatoare trans-sectoriale, May 22-23, 2023, Bucharest, Romania (oral presentation)

- D. Panaitescu, S. Vizireanu, A. Frone, C. Stancu, R. Gabor, C. Nicolae, V. Mărăscu, C. Uşurelu, V. Sătulu, Modification of the surface properties of biopolymers blends by cold plasma treatment, 21st International Balkan Workshop on Applied Physics, July 11-14, 2023, Constanţa, Romania (oral presentation)

- D. M. Panaitescu, S. Vizireanu, V. Sătulu, C-A. Nicolae, C. D. Uşurelu, G. M. Oprică, M. Ghiurea, C. Stancu, A. N. Frone, Cellulose oxidation induced by plasma in liquid treatment, Scientific congress POLY-K 2023 „Advances in polymer composites and nanocomposites”, September 13-15, 2023, Terni, Italy (poster)

- G. M. Oprică, C. D. Ușurelu, A. N. Frone, B. E. Lixandru, A. R. Gabor, C-A. Nicolae, R. C. Fierascu, D. M. Panaitescu, Nanocellulose sponges containing antibacterial natural products, Scientific congress POLY-K 2023 „Advances in polymer composites and nanocomposites”, September 13-15, 2023, Terni, Italy (oral presentation)

- S. Vizireanu, V. Satulu, C. Stancu, A. Bonciu, G. Dinescu, D. Panaitescu, A. N. Frone, C. A. Nicolae, Optimization of plasma in liquid treatment for modification of cellulose suspensions, XXth International Conference on Plasma Physics and Applications, June 13-16, 2023, Iaşi, Romania (poster)

- G-M. Oprică, C-D. Ușurelu, A. N. Frone, R. C. Fierăscu, C-A. Nicolae, I. Caras, S. Vizireanu, D. M. Panaitescu, Dressings based on poly (3-hydroxybutyrate-co-3-hydroxyvalerate) and a phenolic natural product, NeXT-Chem Workshop VIth Edition, March 21-22, 2024, Bucharest, Romania (oral presentation)

- G-M. Oprică, C-D. Ușurelu, C-A. Nicolae, I. E. Neblea, R. C. Fierăscu, D. M. Panaitescu, A. N. Frone, Pickering emulsions stabilized using curcumin-loaded TEMPO-oxidized nanocellulose, Polymers 2024 „Polymers for a Safe and Sustainable Future”, May 28-31, 2024, Athens, Greece (poster)

- D. M. Panaitescu, A. N. Frone, G-M. Oprică, C-D. Ușurelu, A. R. Gabor, C. A. Nicolae, B. E. Lixandru, V. Satulu, S. Vizireanu, Layered dressings from biopolymers and natural antibacterial products, Polymers 2024 „Polymers for a Safe and Sustainable Future”, May 28-31, 2024, Athens, Greece (poster)

- S. Vizireanu, V. Satulu, C. Stancu, V. Marascu, A. Bonciu, G. Dinescu, D. Panaitescu, A. Frone, V. Raditoiu, C. Nicolae, M. Oprică, B. Lixandru, C. Coman, Plasma treatments for the improvement of the antibacterial properties of wound dressings, ICLPR-ST, June 16-20, 2024, Crişan Delta Dunării, Romania (poster)

- G-M. Oprică, C-D. Ușurelu, A. N. Frone, C. Firincă, C. A. Nicolae, R. C. Fierăscu, D. M. Panaitescu, Comparative effect of unmodified and surface-modified nanocellulose on the characteristics of nanoemulsions, Fifth edition of the International Conference NanoBioMat, June 19-20, 2024, Bucharest, Romania (oral presentation)

Coordinator:

National Institute for Research & Development in Chemistry and Petrochemistry – ICECHIM

Partners:

National Institute for Laser, Plasma and Radiation Physics – INFLPR RA

Cantacuzino National Military Medical Institute for Research and Development

ICECHIM – Dr. eng. Denis Mihaela Panaitescu