NEW MATERIALS BASED ON POLYLACTIC ACID WITH CONTROLLED FLEXIBILITY – FLEX4PLA

Funding: Romanian Ministry of Education and Research, CNCS – UEFISCDI

Programme: PNCDI III – Human resources – Research projects to stimulate young independent teams 2019, PN-III-P1-1.1-TE-2019-1333

Research domain: PE5_7 – Biomaterials, biomaterials synthesis; PE5_1 – Structural properties of materials

Project title: NEW MATERIALS BASED ON POLYLACTIC ACID WITH CONTROLLED FLEXIBILITY – FLEX4PLA

Financing contract: no. 67/2020

Total funding: 431.900,00 RON

Project duration: 24 months

Period of project implementation: 15.09.2020-14.09.2022

Contractor: National Institute for Research & Development in Chemistry and Petrochemistry – ICECHIM, Bucharest

Project Manager: PhD eng Adriana Nicoleta Frone

E-Mail address: ,

HUMAN RESOURCE ALLOCATION

Frlina one Adriana Nicoleta, CS 1, Project Leader

Corobea Mihai Cosmin, CS 1, Young Researcher

Panaitescu Denis Mihaela, CS 1, Researcher

Teodorescu George-Mihail, ACS, Master’s Student

Iordache Tanta Verona, CS 1, Young Researcher

Florea Ana-Mihaela, CS 3, Post-doc

Raduly Monica Florentina, CS 3, Young Researcher

Afilipoaei Andreea, ACS, PhD Student

Cărăulașu Monica, ACS, Master’s Student

Ușurelu Cătălina Diana, ACS, Master’s Student

PROJECT SUMMARY

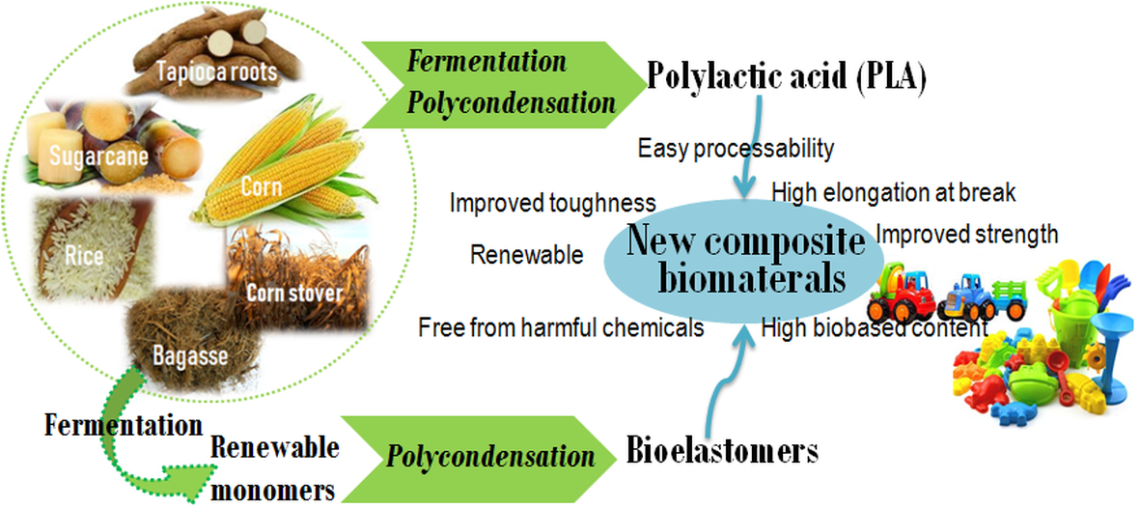

The present project fits into the stream of study and characterization of biobased materials, considering the need to improve their properties from a technological point of view to allow their wider use in final products. Currently, biopolymers have found applications in fields starting from packaging to automotive but an almost unexploited market segment is represented by materials intended for children goods. Most of the global produced toys and other goods for children are made with conventional plastics derived from non-renewable petrochemicals containing dangerous chemical additives to ensure flexibility, natural feel and easy coloring. Thus, the FLEX4PLA project aims the research and design of new biomaterials in which both polymers and additives are being derived from renewable resources. The approach of FLEX4PLA consists in the synthesis of new bioelastomers compatible with PLA from biobased resources and the design of a new technological route to ensure nanodispersion and an engineered interface in PLA/bioelastomers nanomaterials. The new nanomaterials will exhibit the good elasticity of the bioelastomer and the excellent processability of PLA and no more that 10% decrease in strength compared to neat PLA. Tensile properties, impact tests, melt flow index, fracture behavior and morphology will be performed in order to characterize the new biomaterials with the aim of correlating the composition to processability and thus establishing the final properties.

NOVELTY AND ORIGINALITY

FLEX4PLA project will innovate by using new synthesized biobased bioelastomers coupled with NC with controlled surface properties as toughening modifiers and compatibilizer for PLA.

OBJECTIVES

The specific objectives of this project are:

- Setting-up the best conditions for the development of bioelastomer component;

- Designing nanocelulose with controlled hydrophobicity (high and medium level);

- Optimizing the components ratio and technology for PLA/bioelastomer/NC bionanocomposites; sweeping the composition for the best toughness and elongation at break;

- Setting-up the technological conditions for the development of nanocomposite biomaterials model;

- Dissemination of the project results and Protection of Intellectual Property Rights.

ESTIMATED RESULTS

The specific objectives of this project are:

- Setting-up the best conditions for the development of bioelastomer component;

- Designing nanocelulose with controlled hydrophobicity (high and medium level);

- Optimizing the components ratio and technology for PLA/bioelastomer/NC bionanocomposites; sweeping the composition for the best toughness and elongation at break;

- Setting-up the technological conditions for the development of nanocomposite biomaterials model;

- Dissemination of the project results and Protection of Intellectual Property Rights.

PHASES

PHASE I

Title: Setting up the preliminary conditions for synthesis of bioelastomers; Structure and composition analysis; NC functionalization

Period: 15.09.2020 – 31.12.2020

Summary of the activity report

During the 1st phase of FLEX4PLA project, a selection of the raw materials that will be employed for the polycondensation reactions has been made on the basis of the eco-friendly character of the material sources. Sebacic acid was chosen for the preliminary synthesis of the bioelastomers and the synthesis conditions were established. Also during this first stage of this project, several functionalization reactions were performed in order to decrease the hydrophilic characteristics of the nanocellulose. In this regard, two organosilane-type coupling agents and a carboxylic acid were tested. The efficiency of the functionalization reactions was highlighted by specific morpho-structural analyzes (atomic force microscopy – AFM, infrared spectroscopic analysis – FTIR, static contact angle) and thermogravimetric analysis – TGA. The results of the FTIR analysis indicated the presence in the nanocellulose structure of the specific functional groups belonging to the employed functionalization agents. Moreover, the AFM results showed different morphologies of nanocellulose depending of the functionalization agent type. As expected, the modification of the nanocellulose surface with silane coupling agents led to increased of both static contact angles values (from 29 °- control sample to 89 °) and thermal stability.

DISSEMINATION

Conferences:

1. Radu, E.-R.; Panaitescu, D.M.; Gabor, A.R.; Nicolae, C.A.; Frone, A.N. Bio-Based Polyester/Cellulose Films for Engineering Applications. The 16th International Symposium “Priorities of Chemistry for a Sustainable Development” PRIOCHEM, Bucharest, Romania, 28–30 October 2020 (Oral presentation). Proceedings 2020, 57, 36, ISSN 2504 – 3900;

PHASE II

Title: Setting up conditions for the synthesis of bioelastomers; Structure and composition analysis; Development of the new PLA/bioelastomer/NC bionanocomposites

Period: 01.01.2021 – 31.12.2021

Summary of the activity report

In this second phase of FLEX4PLA project, several bioelastomers with different molecular weights were synthesized by polycondensation reactions of varying molar ratios of monomers. The obtained bioelastomers were subjected to detailed morpho-structural (FTIR, AFM), thermal (TGA, DSC) and rheological (MFI, torque) characterizations. Following the obtained results, the bioelastomers with the best thermal performances as well as a low viscosity were selected. The selected bioelastomers were tested as plasticizers in the PLA matrix (2.5 – 20 wt%) using the melt blending process. Thus, various weight ratios between the components of the mixtures were used, and the processing parameters were varied in order to select the best processing conditions (methodology for obtaining PLA/bioelastomers mixtures). The PLA/bioelastomer mixtures that led to the best results in terms of low melt viscosity, low glass transition temperature but also displayed optimal ratio between thermal stability/mechanical strength were subsequently used for the preparation of the PLA/bioelastomer/NC bionanocomposites. In order to obtain an improved dispersion of both bioelastomers and NC in the PLA matrix, a series of masterbatches consisting of bioelastomers, PHB and NC (methodology for obtaining PLA/bioelastomers/NC masterbatches) were obtained. The bionanocomposites were obtained both by direct melt mixing of the components and by diluting the masterbatches in the PLA matrix using various melt processing techniques (extrusion and injection). The bionanocomposites structure/properties relationship was established based on static (tensile elongation and tensile strength) and dynamic mechanical properties, impact strength, small-scale mechanical properties (nanoindentation) and thermal behavior (TGA and DSC analysis). Morphological analysis (AFM and SEM) are currently underway to evaluate the dispersion of NC and bioelastomer particles in the PLA matrix and the best method for obtaining bionanocomposites as well as their optimal composition is to be selected. Some of the experimental work carried out during this stage was disseminated by sending an article for publication in a journal with an impact factor> 4, by publishing an article in a specialized journal with an impact factor> 9 and by participating at 3 conferences.

DISSEMINATION

Papers:

1. A. N. Frone; M. Ghiurea; C. A. Nicolae; A. R. Gabor; S. Badila, D. M. Panaitescu, Effect of cellulose fibers from different sources in poly(lactic acid)/poly(3-hydroxybutyrate) biocomposites, Journal of Materials Research and Technology, 2021, under review

2. I. Chiulan, D. M. Panaitescu, E.-R. Radu, S. Vizireanu, V. Sătulu, B. Biţă, R. A. Gabor, C. A. Nicolae, M. Raduly, V. Rădiţoiu, Influence of TEMPO oxidation on the properties of ethylene glycol methyl ether acrylate grafted cellulose sponges, Carbohydrate Polymers, 2021, 272, 118458, https://doi.org/10.1016/j.carbpol.2021.118458

Conferences:

1. S. Badila, E.-R. Radu, M. S. Popa, D. M. Panaitescu, M. F. Raduly, A. R. Gabor, C.-A. Nicolae, A. N. Frone*, Properties of PLA films with natural agents for children’s toys, 7th Portuguese Young Chemists Meeting (7PYCHEM), 19-21 May 2021, online (poster);

2. A. N. Frone, E.-R. Radu, S. Badila, G.-M. Teodorescu, M. F. Raduly, C.-A. Nicolae, A. R. Gabor, D. M. Panaitescu, Modification of renewable PLA by melt blending with natural additives, 2nd Bucharest Polymer Conference,9-11 June 2021, online (poster);

3. M. S. Popa, E. R. Radu, D. M. Panaitescu, R. A. Gabor, C. A. Nicolae, M. F. Raduly, A. N. Frone*, The potential of biopolyesters as plasticizers for polylactide, PRIOCHEM XVIIth Edition, 27-29 October 2021, Bucharest, online (oral presentation).

PHASE III

Title: Analysis of processing conditions in relation to nanocomposites structure and properties

Period: 31.12.2021 – 14.09.2022

Summary of the activity report

In the last stage of FLEX4PL project, the experimental work for obtaining PLA/bioelastomer/NC bionanocomposites was continued. In this regard, new masterbatches based on PLA/bioelastomers and two different types o nanocellulose were obtained by melt-mixing. Further, the bionanocomposites were developed by masterbatch dilution into PLA matrix through melt-mixing extrusion, and injection molding processing methods. For maximizing the effect of NC on the stiffness of the PLA/bioelastomer blends and controlling the interface, varying compositions and processing conditions were tested. The structure/properties relation of the resulted bionanocomposites was assessed through different investigations: elongation at break and tensile strength by quasi-static and dynamic tensile tests, thermal behavior through TGA and DSC analysis, while the dispersion of the NC and bioelastomer particles in the PLA matrix at micro level was evaluated by SEM. Based on the obtained results, the best bionanocomposites formulations which present good elasticity and processability, as well as balanced stiffness-toughness, were selected and the optimum technological conditions for the development of FLEX4PLA model were established. The demonstration of the FLEX4PLA model was done through specific analyzes that highlighted the degree of

achievement of the planned targets, i.e. high flexibility without the drastic decrease in stiffness. Thus, the results of the mechanical analyzes indicated

an important increase in elongation at break as compared to the PLA matrix and a decrease in the modulus of elasticity lower than 20%. Part of the

experimental work carried out during this last stage was disseminated by two published articles (IF=4.927 and 8.025), two articles in evaluation (IF=4.755

and 4.967), by sending a patent application, and by participating in 4 conferences. Also, the concept of FLEX4PLA project received the Diploma of

Excellence from the Scientific Committee of the 14th edition of EUROINVENT- European Exhibition of Creativity and Innovation as well as the Excellence

Award granted by the “Carol Davila” University of Medicine and Pharmacy, Bucharest.

DISSEMINATION

Papers

- Frone, A.N.; Popa, M.S.; Uşurelu, C.D.; Panaitescu, D.M.; Gabor, A.R.; Nicolae, C.A.; Raduly, M.F.; Zaharia, A.; Alexandrescu, E. Bio-Based Poly(lactic acid)/Poly(butylene sebacate) Blends with Improved Toughness. Polymers 2022, 14, 3998. https://doi.org/10.3390/polym14193998

- A. N. Frone; M. Ghiurea; C. A. Nicolae; A. R. Gabor; S. Badila, D. M Panaitescu, Poly(lacti acid)/Poly(3-hydroxybutyrate) Biocomposites with Differently Treated Cellulos Fibers, Molecules 2022, 27(8), 2390; https://doi.org/10.3390/molecules27082390;

- M. S. Popa, A. N. Frone, D. M. Panaitescu, Polyhydroxybutyrate blends: A solution for biodegradable packaging?, International Journal of Biological Macromolecules, 2022, 207, 263-277; https://doi.org/10.1016/j.ijbiomac.2022.02.185;

- A. N. Frone, D. D. Baciu, M. S. Popa, C. A. Nicolae, A. R. Gabor, M. Florentina Raduly, R. C. Fierascu, D. M. Panaitescu. Thermal behavior and thermo-mechanical properties of biocompatible poly(lactic acid)/allyl-POSS nanohybrids. Under evaluation at Journal of Thermal Analysis and Calorimetry.

Conferences:

1. A. N. Frone*, D. M. Panaitescu, A. Afilipoaei, G. M. Teodorescu, M. S. Popa, A. R. Gabor, C.A. Nicolae, C. D. Usurelu, Thermal and mechanical behavior of PLA plasticized by a bio-derived plasticizer, Polymers 2022 – New Trends in Polymer Science: Health of the Planet, Health of the People, 25-27 May 2022, Turin, Italy (poster).

2. A. N. Frone*, New materials based on polylactic acid with controlled flexibility (FLEX4PLA), 14 thedition of EUROINVENT- European Exhibition of Creativity and Innovation, 26-28 May 2022, Iaşi, România and online. Proceedings of the 14 th edition of EUROINVENT- European Exhibition of Creativity and Innovation, ISSN 2601-4564;

3. A. N. Frone, C. D Uşurelu*, M. S. Popa, A. Afilipoaei, F. M. Raduly, A. R. Gabor, C. A. Nicolae D. M. Panaitescu, Thermal and thermo-mechanical performances of PLA modified with low molecular weight biopolyesters, 1st Central and Easter European Conference on Physical Chemistry & Materials Science (CEEC-PCMS1), 26-30 July 2022, Split, Croatia (poster);

4. C.-D. Uşurelu*, D. M Panaitescu, A. R. Gabor, C. A. Nicolae, A. Afilipoaei, G. M. Teodorescu, A. N Frone, Tuning PLA’s properties using a masterbatch containing plasticize PHB and nanocellulose, 19th Edition of Advanced Nanomaterial Conference (ANM), 28-29 July 2022, Aveiro, Portugal and online (oral presentation).

Patents:

1. Patent application no. A2022 -00494/12.08.2022 Biodegradable linear aliphati copolyester compositions and biopolymers modified with them, production proces and utilization process. A. N. Frone, D. M. Panaitescu, C.-D. Uşurelu, A. R. Gabor, C. A. Nicolae, D. Radu.

Others:

1. The concept of FLEX4PL project received the Diploma of Excellence from the Scientific Committee of 14t edition of EUROINVENT- European Exhibition of Creativity and Innovation as well as th Excellence Award granted by “Carol Davila” University of Medicine and Pharmacy, Bucharest. A. N. Frone*, New materials based on polylactic acid with controlled flexibility (FLEX4PLA), 14th edition of EUROINVENT- European Exhibition of Creativity an Innovation, 26-28 May 2022, Iaşi, România.

Short description of FLEX4PLA results

FLEX4PLA project aimed the development of materials for children’s goods by exploiting a niche market segment for biopolymers through the design of new biomaterials based on polymers and additives derived from renewable resources and “safe” for both human health and the environment. Therefore, within FLEX4PLA project a series of aliphatic polyesters, poly(butylene sebacates) (PBSes), and copolyesters, poly(butylene sebacates-co-propylene itaconates) aimed to improve the ductility and toughness of PLA were synthesized. Both polyesters and co-polyesters were synthesized via the melt

polycondensation of monomers derived from biomass. The number-average molecular weight (Mn) and glass transition temperature (Tg) of PBSe polyesters were tuned by adjusting the molar feed ratio between the precursor monomers. Subsequently, the synthesized polyesters were employed in the

preparation of PLA/polyester blends via melt compounding, extrusion and injection molding using PBSe concentrations between 2.5 to 20 wt% and carefully established processing parameters. The investigation results showed that PLA blends containing 20 wt% PBSe obtained using a diol molar excess of 50% reach up to 108 % elongation at break and minor damages on the Young’s modulus (presented only ~20% decrease) and thermal stability relative to pure PLA. These results demonstrated the plasticizing effect and incresed efficiency of the synthesized bio-derived polyesters in decreasing the brittleness of PLA. The PLA/polyester blends formulations with the best performances were further used in the development of new bionanocomposites containing surface modified or unmodified nanocellulose (NC) for assuring balanced stiffness-toughness properties. Masterbatch technique was also employed for controlling the interface properties between the different phases of bionanocomposites. The project’s overall results demonstrated the efficiency of the synthesized bio-derived polyesters in overcoming the brittleness and improving the processability of PLA. Moreover, the tunable properties of the resulting PBSe can be of great industrial interest in the context of circular bioeconomy. The most important results are as follows:

- New bioleastomers with different molecular weights;

- NC with tailored hydrophobicity

- PLA/bioelastomer blends with improved ductility

- PLA/bioelastomer/NC masterbatch

- PLA/bioelastomer/NC bionanocomposites with improved toughness and elongation at break

- Flex4PLA model

- 3 published papers (2 in Q1 and 1 in Q2 journals) and 2 in evaluation

- 8 international communications (3 oral presentations)