Technological modular and interconnected platforms for an optimized conversion in market-demanded bioproducts of side-streams specific to Romanian bioeconomy

(InteGral)

Nucleu Programme 2023-2026

Project Responsible: Dr. Diana CONSTANTINESCU-ARUXANDEI

Project Scope

The Romanian Bioeconomy is the least performant in the European Union. One of the main causes is the high percent of primary resources production, with linear value chains, which generates large amounts of sub/co-products. The low valorisation of these co/sub-products negatively impacts the economic performance, reduces the eco-efficiency and increases the environment risks. The Scope of project InteGral is to develop processes for the conversion of sub/co-products (side streams), resulting from the Romanian bioeconomy, into (bio)products and (bio)materials with high added value. InteGral project will contribute to the development of a sustainable bioeconomy, with increased resilience, which responds to the societal provocations.

The General Objective

The General objective of project InteGral is the development of modular processes for new-generation, eco-efficient biorefinery, which aggregate in technological platforms for small dimension biorefinery installations. These types of installations are necessary for the conversion of various side streams into bioproducts and biomaterials, which contributes to the achievement of established targets set by The European Green Deal. The General Objective is correlated with the objective of Nucleu Programme, which refers to The integral, cascade exploitation of regenerable resources.

Specific Objectives

The various stages of cascade biorefinery contributes to the objective of Nucleu Programme, of integral valorisation of regenerable resources and are elaborated, realized, tested, optimized, and integrated within the activities aimed towards achieving the following specific objectives (Ob):

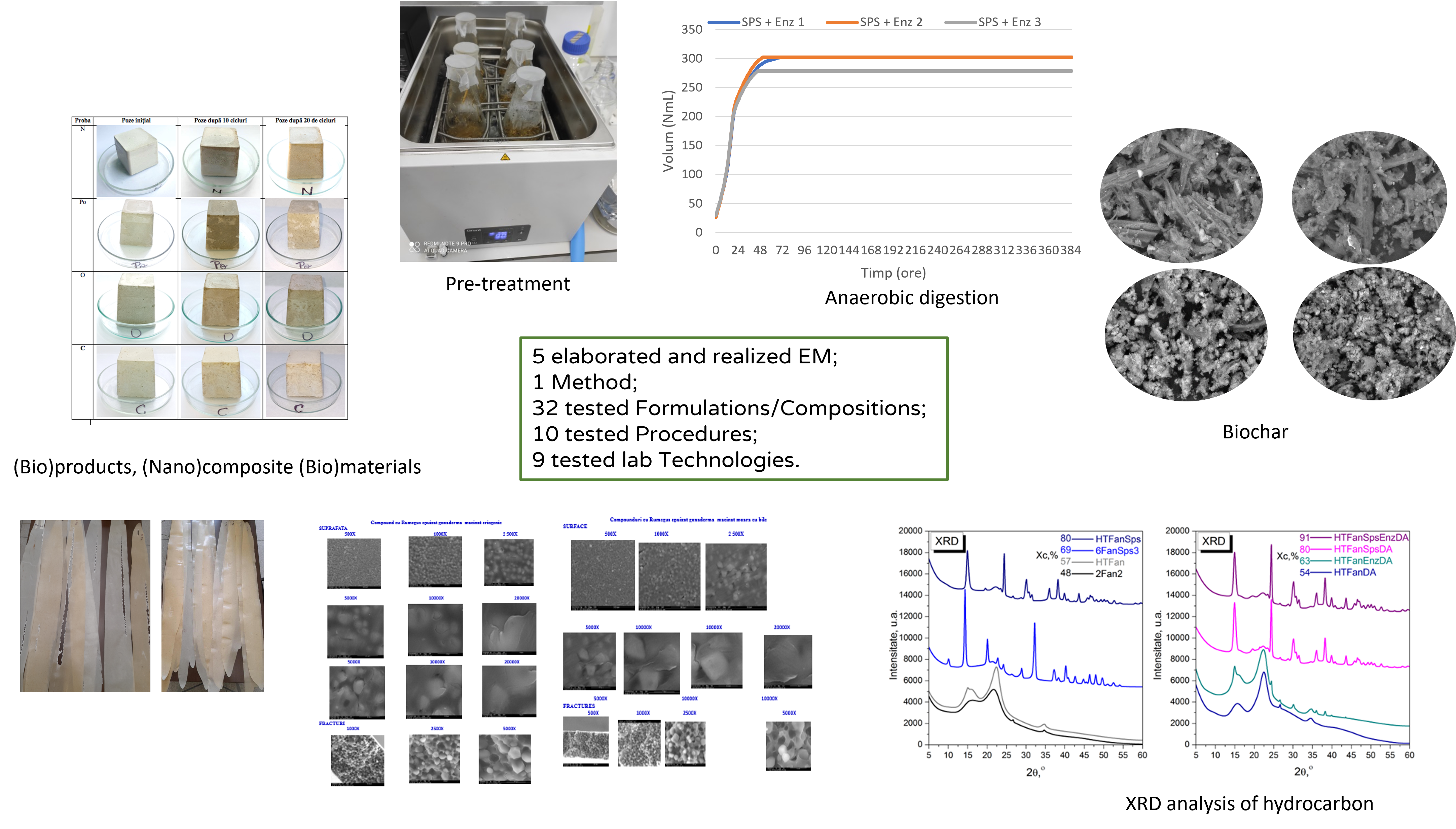

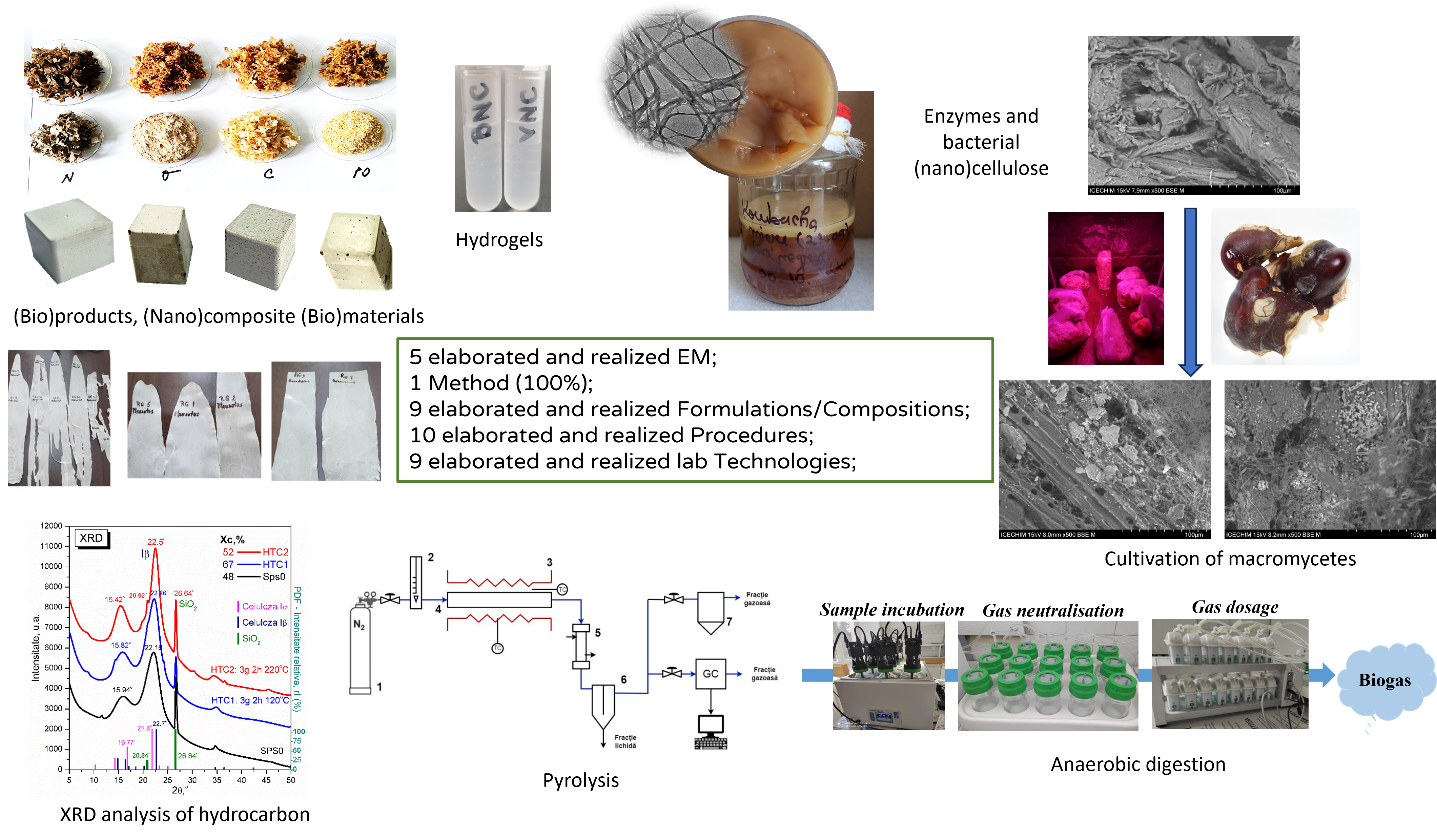

Ob.1. Interconnection of biotechnological processes for in-situ production of enzymes that act on the lignocellulosic matrix, expansins and bacterial cellulose;

Ob.2. Integration of processes for deconstruction of lignocellulosic matrix by biological pre-treatment, bioactive ingredient extraction, fractionation of biopolymers from biomass, and production of fermentable hydrolysates;

Ob.3. Development of interconnected technological solutions for processing the recalcitrant biomass and phosphorous recovery;

Ob.4. Obtaining bioproducts by processing the components recovered from biomass;

Ob.5. Development of (nano)composite (bio)materials by the use of biopolymers and components recovered during biomass processing

Ob.6. Dissemination and communication of results.

Work packages

Each specific objective is planned to be achieved through an associated work package (WP):

WP.1. In-situ production of enzymes, expansins, and bacterial cellulose; WP Responsible – Dr. chim. Diana CONSTANTINESCU-ARUXANDEI

WP.2. Pre-treatment, bioactive ingredient extraction, biopolymer fractionation and production of fermentable hydrolysates; WP Responsible – Dr. ing. Ștefan-Ovidiu DIMA

WP3. Recalcitrant biomass processing and phosphorous recovery; WP Responsible – dr. ing. Gabriel VASILIEVICI

WP.4. Processing of recovered components from the lignocellulosic biomass for obtaining bioproducs; WP Responsible – dr. abil. Florin OANCEA

WP.5. Use of the biopolymers and recovered components for (nano)composite (bio)materials; WP Responsible – dr. ing. Denis PANAITESCU

WP.6. Dissemination and communication; WP Responsible – Prof. dr. Rodica Mariana ION

Techno-scientific reports

Phase 1: Elaboration and realization of Experimental Models

Estimated results: 4 elaborated and realized Experimental Models (EM); 1 Method/Methodology; 5 elaborated and realized Formulations/Compositions; 7 elaborated and realized Procedures; 7 elaborated and realized lab Technologies.

Estimated result indicators: 1 patent application; 3 scientific communications; 3 articles sent for publication; 1 PhD thesis.

Obtained results: 5 elaborated and realized EM (125%); 1 Method (100%); 9 elaborated and realized Formulations/Compositions (180%); 10 elaborated and realized Procedures (143%); 9 elaborated and realized lab Technologies (129%).

Obtained result indicators: 1 patent application (100%); 6 scientific communications (200%); 3 articles sent for publication (100%); 1 PhD thesis (100%); 2 prizes at international conferences.

Phase 2: Testing the Experimental Models

Estimated results: 4 tested Experimental Models (EM); 1 Method/Methodology; 5 tested Formulations/Compositions; 7 elaborated and realized Procedures; 7 tested lab Technologies.

Estimated result indicators: 1 patent application; 3 scientific communications; 4 articles sent for publication; 3 Project proposals; 1 PhD thesis.

Obtained results: 5 elaborated and realized EM (125%); 1 Method (100%); 32 tested Formulations/Compositions (640%); 10 tested Procedures (143%); 9 tested lab Technologies (129%).

Obtained result indicators: 2 patent applications (200%); 10 scientific communications (333%); 3 published articles, 4 articles sent for publication (175%), 1 article in preparation; 1 PhD thesis (100%); 1 prize at international conferences; 8 participations and 2 medals (gold, bronze) at invention expositions.