E12: Compozite și Nanocompozite polimerice

Activitatea de cercetare a Echipei 12 – Compozite şi nanocompozite polimerice este orientată pe dezvoltarea de compozite şi nanocompozite polimerice multifuncţionale pe bază de polimeri sintetici şi/sau naturali şi diferite micro/nano umpluturi sintetice şi/sau naturale, cu impact redus asupra mediului sau biodegradabile şi cu proprietăţi specifice ȋmbunătăţite, impuse de diverse utilizări ȋn industrie (auto şi ambalaje), construcţii, agricultură şi biomedicină. In consecinţă, direcţiile de cercetare luate ȋn considerare sunt axate, pe de o parte, pe caracterizarea, modificarea fizică sau chimică și prelucrarea, atât a componentelor, cât și a (nano)compozitelor rezultate, iar pe de alta parte, pe procedeele de obținere și mecanismele de interacțiune. Principalele obiective ale cercetării Echipei 12 constau ȋn ȋmbunătăţirea prelucrabilităţii şi ȋnlocuirea, pe cât posibil, a aditivilor toxici și a polimerilor sintetici cu materiale izolate din resurse naturale și regenerabile. In ultimii 10 de ani, ȋn cadrul unor proiecte naţionale şi europene (PC6, PC7 şi Orizont 2020), Echipa 12 a dobândit cunoştinţe şi a câştigat experienţă ȋn dezvoltarea unor tehnologii de obţinere a unor (nano)compozite, atât pe bază de polimeri sintetici (PP, PMMA, elastomer termoplastic, cauciuc siliconic) cu diferite (nano)umpluturi (nanosilicaţi naturali, cu morfologie lamelară sau tubulară, nanofire de silice, fibre naturale, nanosilice, metasilicat de calciu) cât şi pe bază de biopolimeri (biopoliamidă, poliesteri alifatici, colagen şi celuloză) cu diferiţi agenţi de ranforsare (structuri 2D grafenice şi nongrafenice, nanofibre de celuloză), implementate şi validate la nivel de TRL 5-TRL 9, pentru fabricarea de: • Componente auto de ȋnaltă calitate (bară paraşoc, formă de depozitare roată de rezervă, stâlp-B) • Ambalaje alimentare • Produse de uz veterinar • Produse biomedicale • Acoperiri de protecţie

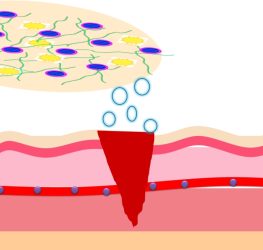

Structuri biopolimerice obținute prin tratament cu plasmă pentru vindecarea rănilor – BIOPLASM

Scopul proiectului este de a obține pansamente eficiente pentru tratamentul rănilor infectate prin dezvoltarea nanopurtătorilor de nanoceluloză antibacterieni depuși pe un substrat de poliester alifatic.

Design of new nanocellulose-based gas-carrier systems

The scope of the CELGAS project is to develop innovative oxygen-carrying systems capable of supplying oxygen in a controlled manner to injured tissue/implants or intravenously.

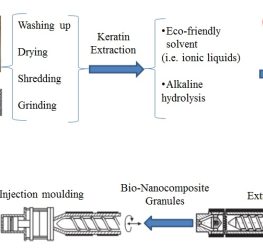

Nanocompozite ecologice pe bază de bio-PA și bio-umpluturi pentru piese auto injectate ECONANO4AUTO

Scopul proiectului il reprezinta obținerea de nanocompozite bio-polimerice cu proprietăți îmbunătățite, reciclabile, reutilizabile și bio-integrabile la sfârșitul ciclului de viață, pe bază de bio-PA și keratina din pene de pui.

Adriana N. Frone, Catalina D. Usurelu, Gabriela M. Oprica, Denis M. Panaitescu, Augusta R. Gabor, Cristian A. Nicolae, Florin Ciuprina, Celina M. Damian

Contribution of the Surface Treatment of Nanofibrillated Cellulose on the Properties of Bio-Based Epoxy Nanocomposites Intended for Flexible Electronics

International Journal of Molecular Sciences

https://doi.org/10.3390/ijms24076544

Denis M. Panaitescu, Adriana N. Frone, Cristian A. Nicolae, Augusta R. Gabor, Dana M. Miu, Mariana G. Soare, Bogdan S. Vasile, Irina Lupescu

Poly(3-hydroxybutyrate) nanocomposites modified with even and odd chain length polyhydroxyalkanoates

International Journal of Biological Macromolecules

https://doi.org/10.1016/j.ijbiomac.2023.125324

Denis M. Panaitescu, Marius S. Popa, Florin Ciuprina, Laura Enache, Adriana N. Frone, Cristian A. Nicolae, Augusta R. Gabor, Roxana Trusca, Valentin Raditoiu, Bogdan Trica, Marius Ghiurea

Role of polyaniline coating on nanosilica particles in polyvinylidene fluoride nanocomposites for energy storage

Surface and Interfaces

https://doi.org/10.1016/j.surfin.2022.102546

Oprică, G.M.; Panaitescu, D.M.; Usurelu, C.D.; Vlăsceanu, G.M.; Stanescu, P.O.; Lixandru, B.E.; Vasile, V.; Gabor, A.R.; Nicolae, C.-A.; Ghiurea, M; Frone, A.N.

Nanocellulose Sponges Containing Antibacterial Basil Extract

International Journal of Molecular Sciences

https://doi.org/10.3390/ijms241411871

Andreea Ionita (Afilipoaei), Zina Vuluga, Florin Oancea, George M. Teodorescu, Raluca A. Gabor, Cristian A. Nicolae, Malina Desliu – Avram, Jenica Puceagiu

Properties of Composites based on Recycled Polypropylene and Lignocellulosic Agricultural Waste

Revista Română de Materiale

https://solacolu.chim.upb.ro/pg94-100.pdf

Ianchis, R., Munteanu, T., Ninciuleanu, C. M., Gifu, I. C., Alexandrescu, E., Somoghi, R., Gabor, A. R., Preda, S., Nistor, C. L., Nitu, S., Petcu, C.

The Effect of Clay Type on the Physicochemical Properties of New Hydrogel Clay Nanocomposites

În: Current Topics in the Utilization of Clay in Industrial and Medical Applications, Mansoor Zoveidavianpoor, IntechOpen

978-1-83881-554-7

Corobea, M.C., Vuluga, Z., Florea, D., Miculescu, F., Voicu, S.I.

Composites and Nanocomposites Based on Polylactic Acid

Capitolul 13, pp. 327-360 în: “Handbook of Composites from Renewable Materials, Nanocomposites : Advanced Applications”, Eds: Thakur V.K., Thakur M.K., Kessler M.R.,Wiley and Scrivener Publishing, 2017

978-1-11-922383-2

Donescu, D., Corobea, M.C.*, Spataru, C.I., Ghiurea, M.

Polymer carbon nanotubes composites obtained via radical polymerization in water-dispersed media

Capitol 11, pp. 281-305 în: Woodhead Publishing Series in Composites Science and Engineering “Hybrid Polymer Composite Materials Processing” 2017 Elsevier Ltd.

978-0-08-100790-7

Z. Vuluga, F. Oancea, D.M. Panaitescu, A.N. Frone, C.A. Nicolae, A.R. Gabor, A. Ionita, G.M. Teodorescu, M. Ghiurea, V. Faraon, G. Vasilievici, G.M. Oprica

Keratin/nanoparticle hybrids for bio-PA nanocomposites

XIXth Edition of the International symposium “PRIORITIES OF CHEMISTRY FOR A SUSTAINABLE DEVELOPMENT” (PRIOCHEM XIX 2023), Bucharest, Romania, October 11-13, 2023

G.-M. Oprica, C.D. Usurelu, A.N. Frone, B.E. Lixandru, V. Vasile, M. Ghiurea, A.R. Ghiurea, C.-A. Nicolae, P.O. Stanescu, D.M. Panaitescu

Treatment of nanocellulose by antibacterial agents of natural origin

XIXth Edition of the International symposium “PRIORITIES OF CHEMISTRY FOR A SUSTAINABLE DEVELOPMENT” (PRIOCHEM XIX 2023), Bucharest, Romania, October 11-13, 2023

Ș-O. Dima, D. Constantinescu-Aruxandei, N. Tritean, M. Ghiurea, C-A. Nicolae, C. Neamtu, F. Oancea

Analytic fingerprints of Se-stimulated cabbage biofortification

XIXth Edition of the International symposium “PRIORITIES OF CHEMISTRY FOR A SUSTAINABLE DEVELOPMENT” (PRIOCHEM XIX 2023), Bucharest, Romania, October 11-13, 2023

M. Desliu-Avram, B. Trica, M.F. Raduly, C-A. Nicolae, M. Ladaniuc, D. Constantinescu-Aruxandei, D. Dimonie

The spending of wood sawdust as possibility to improve the embedding’s efficiency into renewable origin polymeric matrices

XIXth Edition of the International symposium “PRIORITIES OF CHEMISTRY FOR A SUSTAINABLE DEVELOPMENT” (PRIOCHEM XIX 2023), Bucharest, Romania, October 11-13, 2023

T. Fistos, A. Melinescu, L.M. Ditu, A. Ficai, D. Ficai, F. Marinescu, R.I. Matei (Brazdis), I. Fierascu, A.M. Baroi, C.A. Nicolae, R.C. Fierascu

Multifunctional composite materials (with consolidation, self-cleaning and antimicrobial properties) applicable for the preservation of inorganic substrates

XIXth Edition of the International symposium “PRIORITIES OF CHEMISTRY FOR A SUSTAINABLE DEVELOPMENT” (PRIOCHEM XIX 2023), Bucharest, Romania, October 11-13, 2023

R.I. Matei (Brazdis), A.M. Baroi, R.C. Fierascu, T. Fistos, I.E. Chican, G. Ivan, I.S. Hosu, C.A. Nicolae, I. Fierascu

Preliminary assessment for heavy metal removal from synthetic water matrix using an organic/inorganic composite

XIXth Edition of the International symposium “PRIORITIES OF CHEMISTRY FOR A SUSTAINABLE DEVELOPMENT” (PRIOCHEM XIX 2023), Bucharest, Romania, October 11-13, 2023

G.M. Teodorescu, Z. Vuluga, F. Oancea, A. Ionita, V. Faraon, G. Vasilievici

Mechanical, dynamic-mechanical and nanomechanical properties of biopolyamide/keratin nanocomposites

XIXth Edition of the International symposium “PRIORITIES OF CHEMISTRY FOR A SUSTAINABLE DEVELOPMENT” (PRIOCHEM XIX 2023), Bucharest, Romania, October 11-13, 2023

G.M. Teodorescu, Z. Vuluga, A.N. Frone. G.M. Oprica, C.D. Usurelu, T. Fistos, A.M. Baroi, R.I. Matei, R.A. Gabor, C.A. Nicolae

The mechanical, thermal, and nanomechanical properties of composites made of bio-based polyamide and ash powder

XIXth Edition of the International symposium “PRIORITIES OF CHEMISTRY FOR A SUSTAINABLE DEVELOPMENT” (PRIOCHEM XIX 2023), Bucharest, Romania, October 11-13, 2023

C-D. Uşurelu, G-M. Oprică, A.N. Frone, E-I. Neblea, M.F. Raduly, A.R. Gabor, C-A. Nicolae, M. Teodorescu, D.M. Panaitescu

Preparation and functionalization of nanocellulose using lactic acid: morphostructural characterization and emulsifying capacity

XIXth Edition of the International symposium “PRIORITIES OF CHEMISTRY FOR A SUSTAINABLE DEVELOPMENT” (PRIOCHEM XIX 2023), Bucharest, Romania, October 11-13, 2023

O.D.A. Dimonie, I. Toma, A.R. Gabor, C.A. Nicolae, V. Rădiţoiu, F.M. Raduly, M.A. Ladaniuc

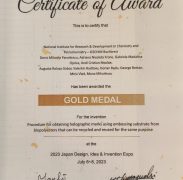

Cerere de brevet de invenţie – Composition based on polymers of renewable origin for sustainable applications in the automotive industry that can be achieved by 3D and/or classic techniques

A2022-00608/05.10.2022

- 1

- 2